decorative film industry

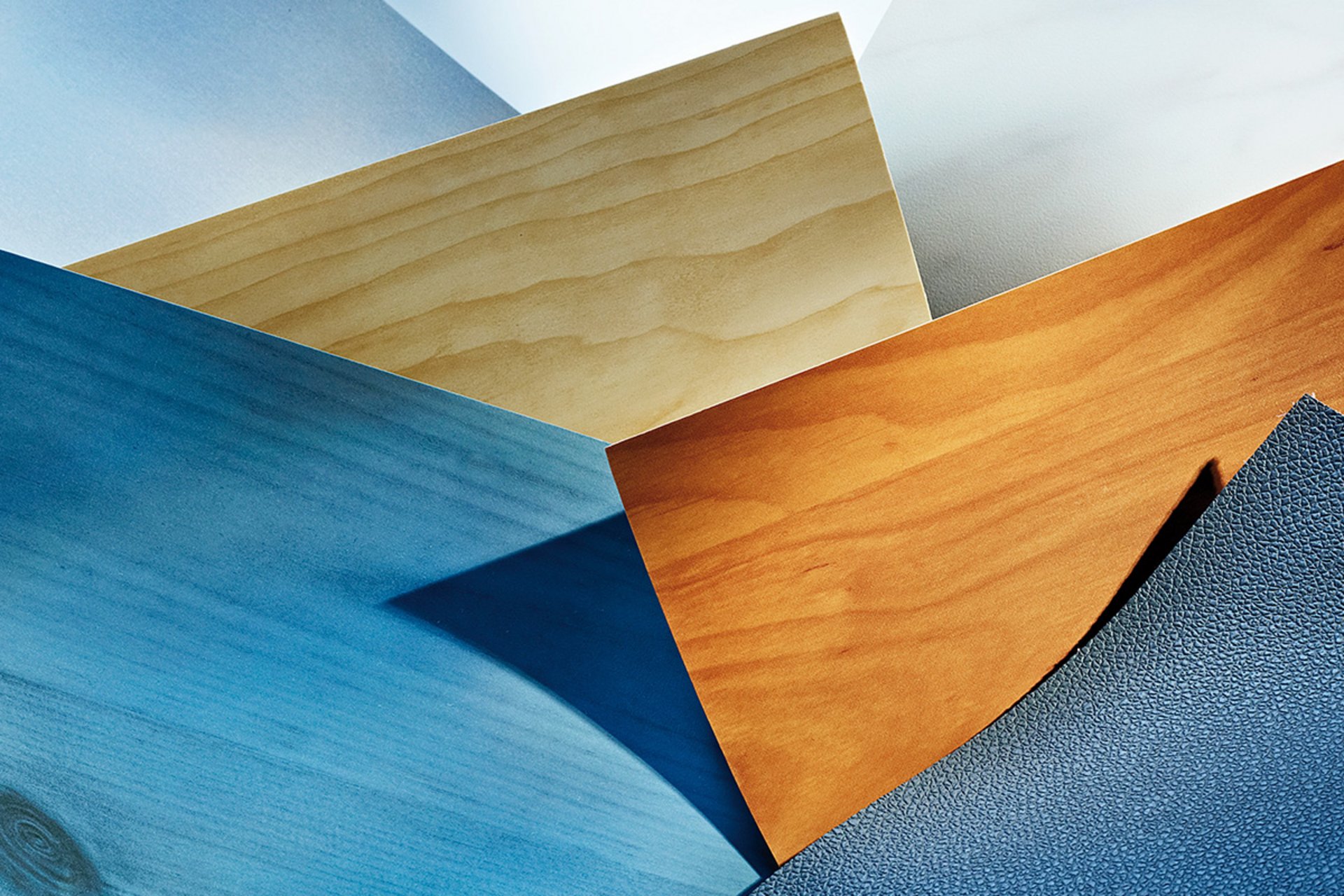

Through our decades of experience in the decorative film industry we know: Your sector has the highest optical demands. This is why OLBRICH has specialized in meeting your quality requirements 100 percent.

Our systems and machines for the decorative film industry are regarded worldwide as a reference for quality - among others by automotive groups and suppliers, artificial leather manufacturers for luxury shoes or bags as well as the major decorative film manufacturers for furniture, windows or stretch ceilings.

On request, we can also provide you with turnkey complete packages from a single source - from conception to extensive tests in our technical centre to production and assembly of your machines. On request, we can also undertake complete factory planning.

Artificial leather coating

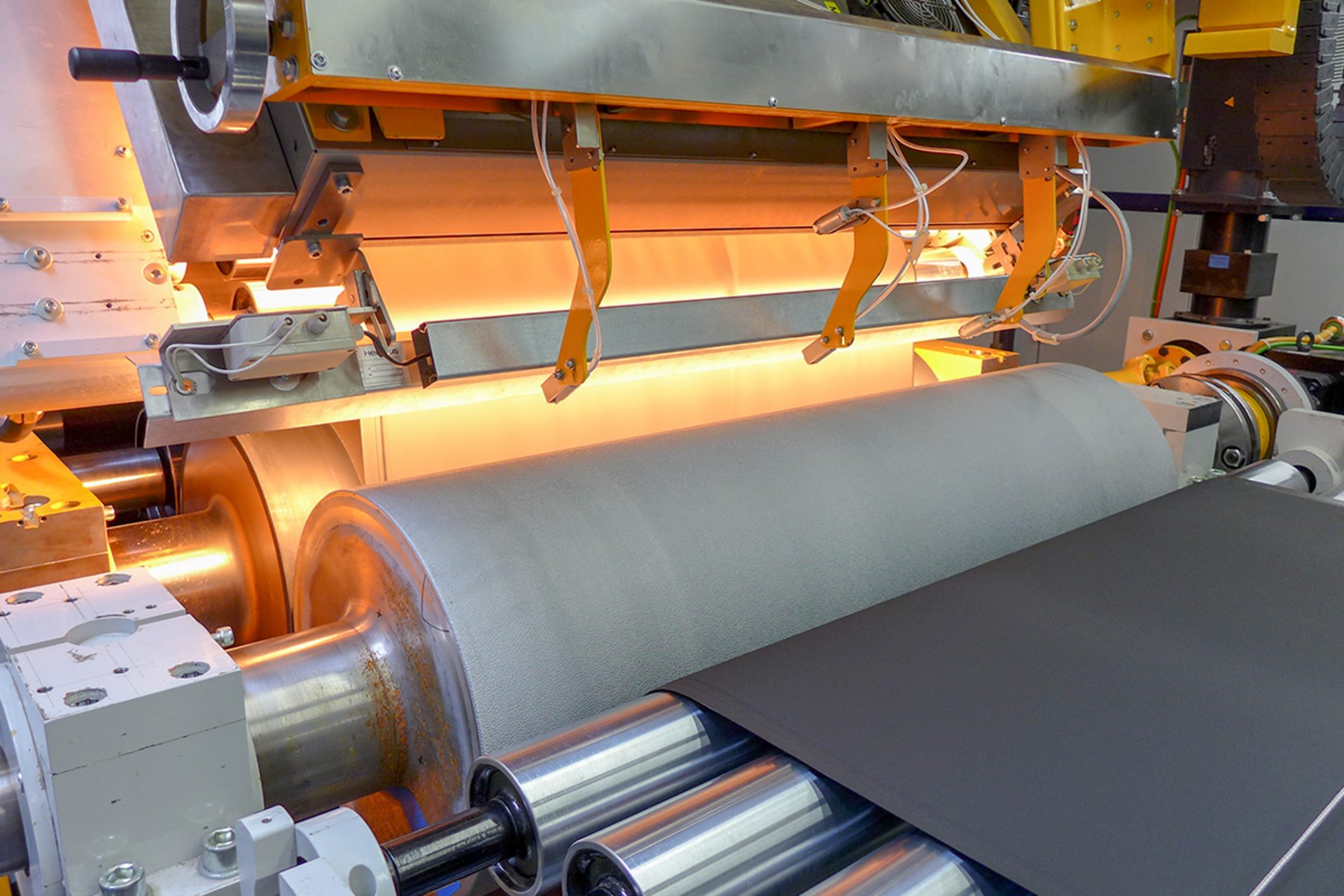

OLBRICH brings about 70 years of experience to each of your coating projects. With this knowledge we have risen in the last decades in the field of transfer coating to a production machinery specialist for all well-known manufacturers: from the automotive industry to the luxury goods industry for artificial leather products.

Coating systems from OLBRICH guarantee maximum precision and reproducibility right from the start. With our systems you can produce all types of PVC and PU films, for example for furniture, luxury shoes and bags, but also for door and side panels, sun visors, seat covers or hat shelves in the automotive industry.

Depending on the product and requirements, we develop coating systems for you with one to four coating stages. The working widths are typically up to 2,400 millimeters. Thanks to high production speeds of up to 50 meters per minute, your business benefits from noticeable increases in performance and efficiency.

Exemplary coating technologies:

- Coating of PVC and PU (with and without solvents)

- Compact films and foamed films

- Coating with a doctor blade (knife over roll)

- Reverse roll coater (RRC)

- Glue application

- Application of PU-coatings

- Lamination of fabrics and knitted fabrics

- Dual-Layer Slot Die

Printing and lacquering decorative films

A defect-free surface image and high-precision registration control are special features of our printing and coating systems. Our machines offer you flexible applicators for forward and reverse lacquering, direct and indirect coating as well as trolley systems for fast product changes. In addition, effective intermediate and final dryers ensure high system speeds so that you achieve efficient and high-quality results. Thanks to our state-of-the-art machine concepts, we are today the market leader in the field of lacquering lines for automotive films.

With systems from OLBRICH, you can print and coat many types of decorative films: In the automotive industry, for example, films for instrument panels, door and side panels, sun visors, seat covers or hat shelves. In the decorative sector, 2D and 3D decorative films are particularly in demand, for example for furniture, window profiles, door panels or ship interiors. Of particularly high-quality are decorative surfaces in "High Gloss" and "Super Matte" finish.

The working widths of our machines for TPO and artificial leather products are up to 2,400 millimeters. Thanks to high production speeds, your company benefits from noticeable increases in performance. With our machines, you can print and coat decorative films up to a width of 2,200 millimetres at speeds of up to 100 metres per minute.

Exemplary printing and coating technologies:

- Inline systems for non-stop design changes while production is running

- Machines for direct and/or indirect lacquer application

- UV lacquering

- Primer coating

- Printing lines with register control systems

- Sleeve technology

- Trolley systems for quick product changes

Drying decorative films

Our wide range of energy-efficient high-performance dryers offers you optimum results for every type of film: OLBRICH systems guarantee high temperature accuracy, perfect reproducibility and uniform drying across the entire width. For higher line speeds, our highly effective and patented horizontal dryers with CTS-TP nozzles are the first choice. Of course, we also supply Exx dryers with the associated concentration detection and control systems.

For the dryer design of your project, we use both computer simulations and drying tests in our technical centre. In this way, our experts determine exactly the necessary dryer lengths depending on your desired production speeds. The dryer temperatures typically are up to 150 °C during production.

Our drying systems are suitable for all types of decorative films: In the automotive industry, for example, for films used in instrument panels, door and side panels, sun visors, seat covers or hat shelves. 2D and 3D decorative films are particularly in demand in the furniture industry, for example for window profiles, door panels and furniture or ship interiors.

Exemplary drying technologies:

- Top air dryer

- Top/bottom air dryer

- Top/bottom air dryer with CTS-TP nozzles (OLBRICH patent)

- Annealing systems

- Gelling ovens

- Foaming ovens

- UV drying systems

Laminating decorative films

When laminating decorative films, our specialists know exactly what is important: low elongation of the material, wrinkle-free film products and low-tension web guidance of sensitive films. In addition, precise temperature control for the different films is important. Our systems guarantee you the highest quality results in all areas mentioned.

With OLBRICH machines you can laminate decorative films with thicknesses between 50 and 600 micrometers as well as automotive films between 0.5 and 5 millimeters. The lamination temperatures are up to 200°C.

Your advantage at OLBRICH: We develop tailor-made solutions for your company - for example for laminating up to six films on a heating drum, for individual laminations or for laminating textiles. In addition, we implement effective line concepts for you for maximum efficiency with multilayer structures.

With our systems, you can perfect the lamination of a wide variety of films: In the automotive industry, for example, films for instrument panels, door and side panels, sun visors, seat covers or hat shelves. Or in the furniture industry, decorative films for window profiles, door panels and ship interiors.

Exemplary laminating technologies:

- Hot laminating lines with central laminating cylinder

- Hot laminating lines with single roller conveyors

- variable pre-heating

- Double, triple and multi-layer laminations

- Cold lamination with adhesive systems

- Infrared heating systems

- delaminating equipment

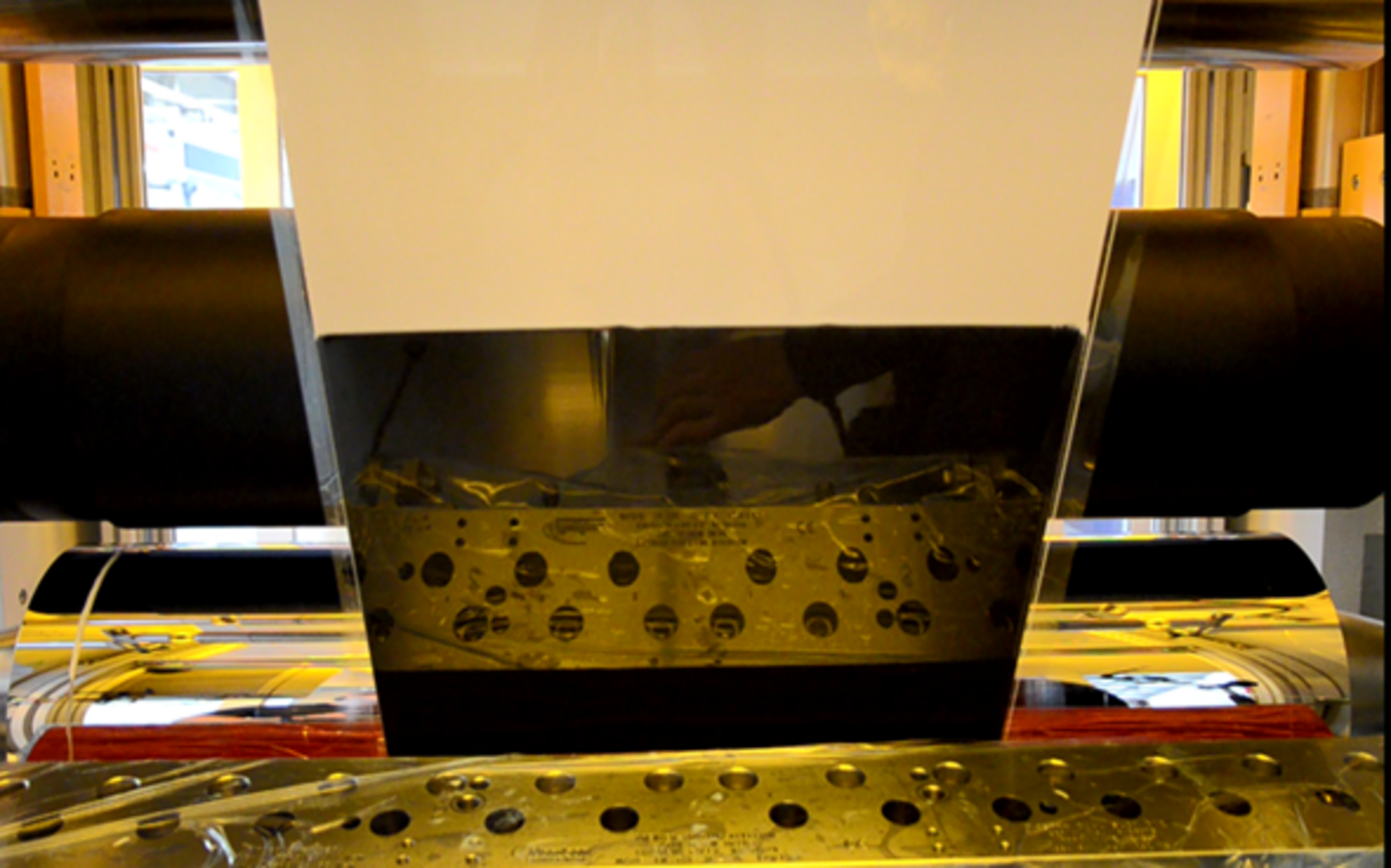

Embossing and smoothing decorative films

With embossing and smoothing systems from OLBRICH, you can rely on maximum reproducibility and particularly defined embossing images. With our precisely coordinated cooling and heating processes and gentle web guidance, you can avoid material shrinkage or stretching just as effectively as distortion of the films in cross machine direction.

Our machines offer you many practical functions for embossing and smoothing: For example quick change of embossing rollers, variable wrap angles at the embossing rollers or spraying devices for cooling the counter roller. Thanks to very high embossing pressures of up to 25 metric tons, you obtain high-quality results. The production speeds are up to 30 meters per minute for automotive films and up to 60 meters per minute for decorative films. The typical working width is up to 2,300 millimeters.

With our systems, you can emboss a wide range of films: In the automotive industry, for example, films for instrument panels, door and side panels, sun visors, seat covers or hat shelves. Well-known fashion labels for luxury goods rely on high-quality artificial leather products embossed in our machines for luxury goods - for example for designer furniture, shoes or bags. In the decorative industry, films for window profiles, door panels, ship interiors or furniture are particularly in demand.

Exemplary embossing/smoothing technologies:

- Horizontal or vertical embossing calenders

- Multi-roll revolver embossing calenders

- Hot and cold embossing machines

- Patrix-Matrix-Systems

- In-Register embossing (synchronous pore)

- Inline and offline concepts

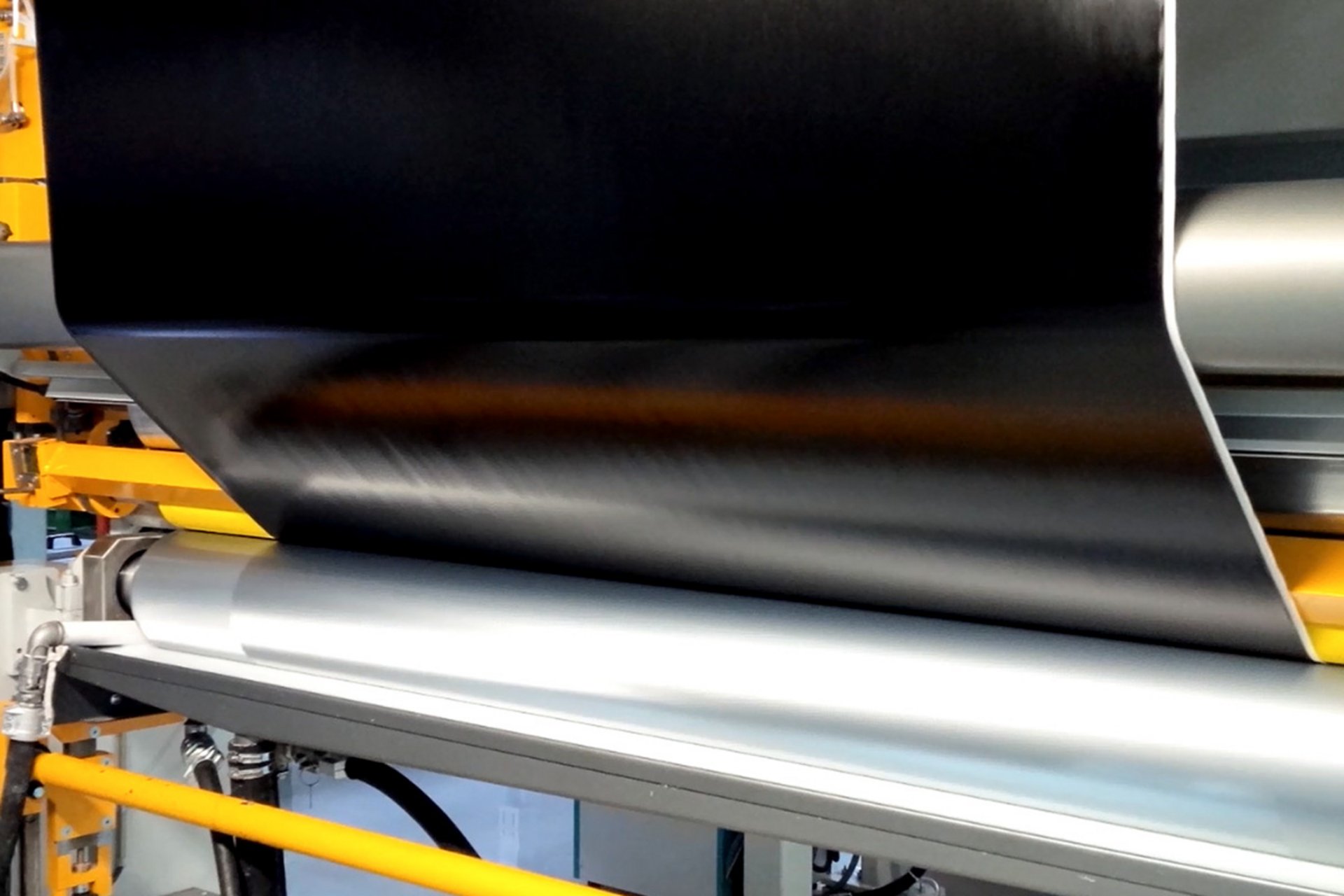

Calendering decorative films

OLBRICH calenders enable you to produce decorative films with particular precision, because all machine components are precisely matched to each other. Thanks to various deflection compensations such as crowning, axe-crossing and roll-bending, you obtain reproducible, high-quality results - even with high shear forces.

Our calender lines process a wide variety of materials, such as soft and rigid PVC as well as TPO/TPU films and sheets. The working widths are up to 4,000 millimeters, the film thicknesses between 50 and 800 micrometers. The machines achieve a high production throughput of up to five tons per hour.

In the furniture industry, the calendering of decorative films is particularly popular, for example for window profiles, door panels or ship interiors. Other products for other industries include graphic films, credit cards, key cards, ID cards and blister packs.

Your advantage at OLBRICH: Our specialists can design and implement complete film production for you on request, including PVC processing, extruders and film finishing.

Exemplary calender technologies:

- 2- and 3-roll film melt roller calender

- 4- and 5-roll film melt roller calender

- Calender with film lamination

- Calender with and without stretching device

- Smoothing calender

- Calibration calender

Winding decorative films

In about 70 years, the machinery experts at OLBRICH have perfected winding technology is for decorative films. With our systems, you can achieve crease-free and tension-free winding of your films, with precise straight edges and practical residual length optimisation. In this way, you effectively avoid production losses in your factory.

With winding systems from OLBRICH you have working widths of up to 2,400 millimetres at your disposal. The production speeds are up to 200 metres per minute. Our automatic feeding systems also facilitate the loading and unloading of jumbo rolls with diameters of up to 1,400 millimeters and weights of up to four metric tons.

Exemplary winding technologies:

- Manual winder with web accumulator

- Automatic turret winders

- Centre slitting and slitting into several sheets

- Winding with and without adhesive preparation at the core

- Winding on cores and without cores

Making decorative products ready for sale

OLBRICH systems enable you to manufacture your decorative films to a particularly high standard of quality: we design tailor-made solutions for you that save you time effectively. Straight-edged customer rolls ensure perfect packaging results.

Your decorative films can be made ready for sale either manually or with automatic solutions. The working widths are up to 2,400 millimetres. For maximum precision, all length measurements are made with calibrated length counters.

With our systems, you can easily and safely make many different types of decorative films ready for sale: In the automotive industry, for example, films for instrument panels, door and side panels, sun visors, seat covers or parcel shelves. 2D and 3D decorative films are particularly in demand in the furniture industry, for example for window profiles, door panels or ship interiors.

Exemplary technologies:

- Single rewinder/unwinder

- Double rewinder/unwinder

- Rewinding machines

- Short reel winder

Decorative foils: Drive and control technology

Maximize your production and data security: With drive and control technology from OLBRICH, you can rely on safe processes in the production of decorative films. In this way, you receive all services from one experienced source: We supply you with the mechanical drive and suitable switchgear with OLBRICH state-of-the-art technologies for your plant. In this way, machine technology and control plants are optimally matched to each other.

With our own specialists in the electrical sector, we implement innovative and safe solutions for you in the areas of drive and control technology, user interfaces and visualisation/scada systems on the basis of various software platforms. The sophisticated architecture of our systems also enables you to retrofit functions and units later on. In addition, we also retrofit existing systems with state-of-the-art technologies.

Your benefit at OLBRICH: We take local standards and your specific requirements into account. In addition, our highly qualified specialists have many years of experience with all common PLC controls, for example from Siemens, Rockwell/Allen Bradley or Schneider. On request, we can also develop extended recipe administration for you for fast product changes or the creation of production trends.

In addition, you can rely on our reliable and fast service - via remote maintenance and with promptly available service technicians.

Exemplary services for drive and control technologies:

- Conception and realization of the drive technology

- Switchgear planning and manufacturing

- Software engineering for CPU

- Visualization / Scada systems

- Support and assistance with IQ and OQ

- Service over the entire life cycle

- Retrofittings and Upgrades

Services in a full-service package

We implement your individual project in six carefully coordinated steps: