Further branches

Tailor-made solutions for a wide range of applications are our strength. Tell us your individual requirements for the production of web-shaped products - and our specialists will develop high-performance machines and systems for your individual application.

Together with your company, OLBRICH designs new processes for products beyond the standard. Possible applications include coating lines for films in the electrical industry, display films, insulating materials and foams, laminating lines for composite materials as applications in industry and vehicle construction as well as embossing lines for most different products.

Your added value at OLBRICH: You benefit from more than 70 years of experience in machine and plant construction for a wide variety of industries. In our own pilot plant, we reliably optimize your machines until they are ready for application. For individual projects, we also benefit from the know-how of our brand Polytype Converting® in the field of high-precision coating processes.

Coating systems for a wide range of applications

Do you have special requirements for coating web-shaped products? OLBRICH offers you a wealth of experience in a wide range of applications: from for instance "wet-on-wet" coatings with scatter coated particles particles up to clean room coating lines. Depending on the coating media, application quantities ranging from one gram to several kilograms per square meter are possible.

Are you thinking about novel coatings and looking for an experienced partner for the further development of suitable processes? Our engineering specialists will be happy to advise you in detail and implement special solutions as well as tailor made machines for you.

Just get in touch with us!

Printing and lacquering of web-shaped products

Standard printing systems do not offer you the right solution for your special products? Or do you have special requirements for printing and lacquering web-shaped products? OLBRICH realises screen, gravure and flexographic printing technologies for you from just one single source. Our machines process both solvent-based and aqueous inks and lacquers.

Do you want to test new applications? Our engineering specialists will be happy to advise you in detail and implement special solutions as well as tailor made systems for you.

Just get in touch with us!

Drying technology for web-shaped products

Do you have special requirements for drying web-shaped products? OLBRICH dryers earned an excellent reputation in many industries: from GMP-compliant designs and clean room systems - also for EEX operation (ATEX) - to high-performance foaming and fusion ovens for PVC applications.

Do your coating media require specific drying processes? Or do you need an individual symbiosis of different drying technologies? Our engineering specialists will be happy to advise you in detail and implement special solutions as well as tailor made systems for you.

Just get in touch with us!

Laminating and bonding special products

Do you have special requirements for laminating and bonding your web-shaped products? OLBRICH develops for you individual technical solutions for different products: Our machines for wet laminating, thermal bonding or adhesive lamination offer you a wide range of options. At the same time, OLBRICH offers you a unique wealth of experience from about seven decades – from simple laminating systems up to complex, multi-layer laminating lines.

Our experienced engineering specialists will be happy to advise you in detail and implement special solutions as well as tailor made systems for you.

Just get in touch with us!

Embossing and smoothing special products

Do you have special requirements for embossing and smoothing paper, films or other web-shaped products? Perhaps the previous embossing quality of your products is no longer sufficient? Or do you notice different demands for new products?

With our many years of experience in a wide variety of industries, we know that different products require specific boundary conditions and process windows. For extensive tests in the development phase, we therefore use a dedicated embossing and laminating line in our technical centre.

Our engineering specialists will be happy to advise you in detail and implement special solutions as well as individually designed systems for you.

Just get in touch with us!

Calender special films

Do you have special requirements for calendering films or web-shaped products? We realize plants for reproducible production results: from individually developed melt roll calenders with up to four meters working width up to special calibration calenders with bending compensation of the process rolls.

Perhaps you would also like to display new products or configure your new machine individually? Our engineering specialists will be happy to advise you in detail and implement tailor made solutions for you.

Just get in touch with us!

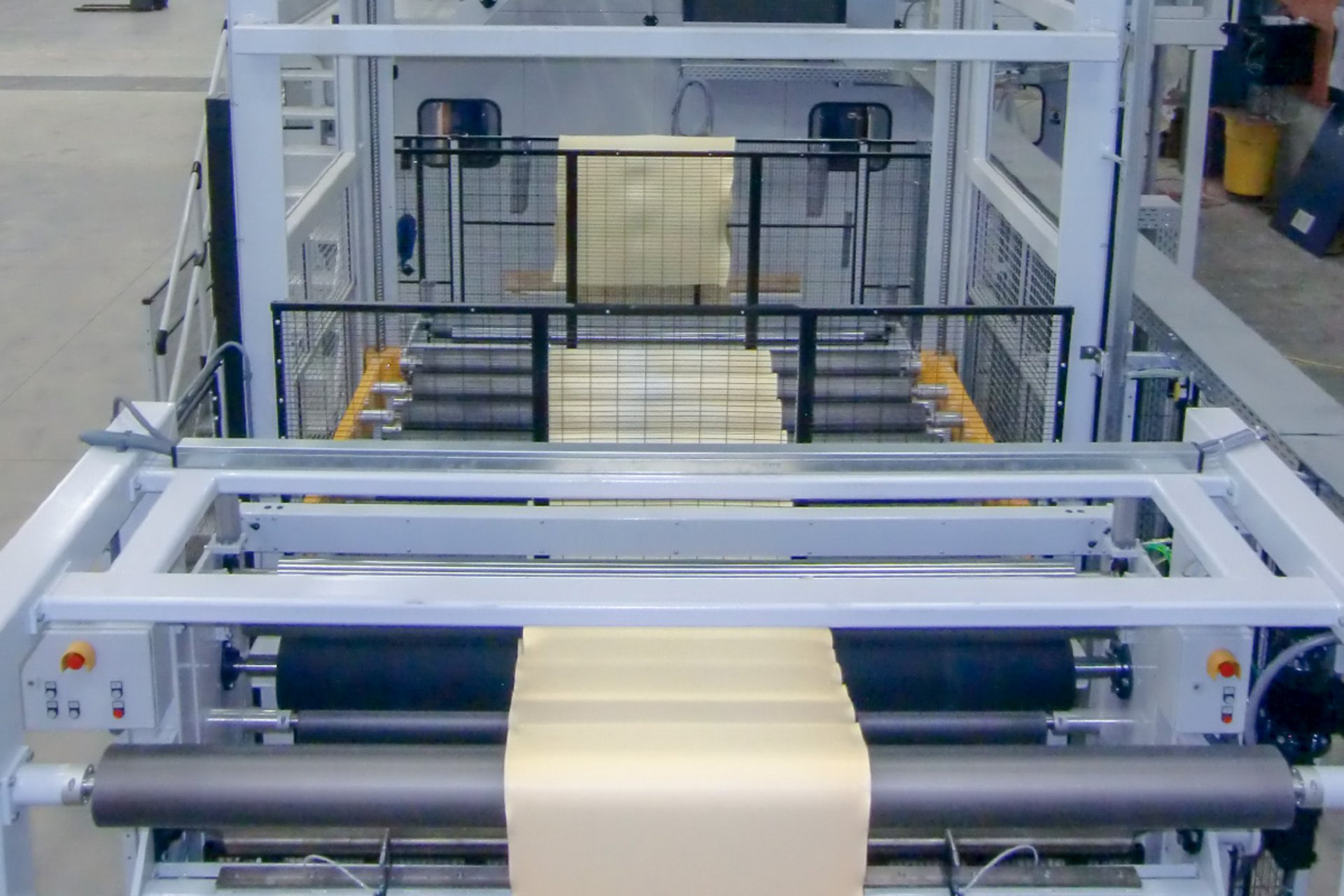

Winding special products

Do you have special requirements for the winding of your web-shaped products? Do you want to automate the winding operation by large? Or are your products particularly sensitive to tension or pressure?

We can implement special winding systems for you according to your requirements: from the simple, manual winding station to the automatic turret winder with fully automatic core handling and bale removal. By the way: For good reasons, other manufacturers also rely on OLBRICH winders to up-grade their already existing machines and plants.

Our experienced engineering specialists will be happy to advise you in detail and implement tailor made solutions.

Just get in touch with us!

Making products ready for sale

Do you have special requirements making your products ready for sale? Would you like to discharge and pack roll goods? Cutting and staking sheets or slabs? OLBRICH winding and packaging machines are not only the benchmark for quality for wallpapers and floor coverings - our machines also reliably produce foam, decorative films and many more.

Our experienced engineering specialists will be happy to advise you in detail and implement special solutions and tailor made systems for you.

Just get in touch with us!

Tailor-made drive and control technology

Do you have special requirements in the field of drive and control technology for your new systems or already existing plants? Do you wish to use special components? Or an interface to your production planning and control system?

We develop tailor-made drive and control plants for you in the proven OLBRICH quality according to your requirements. Integrated recipe management and state-of-the-art user interfaces (HMI) are a matter of course for us.

Our drives and controls specialists will be pleased to advise you in detail and implement individual drive solutions as well as control systems for you.

Just get in touch with us!

Services in a full-service package

We implement your individual project in six carefully coordinated steps: