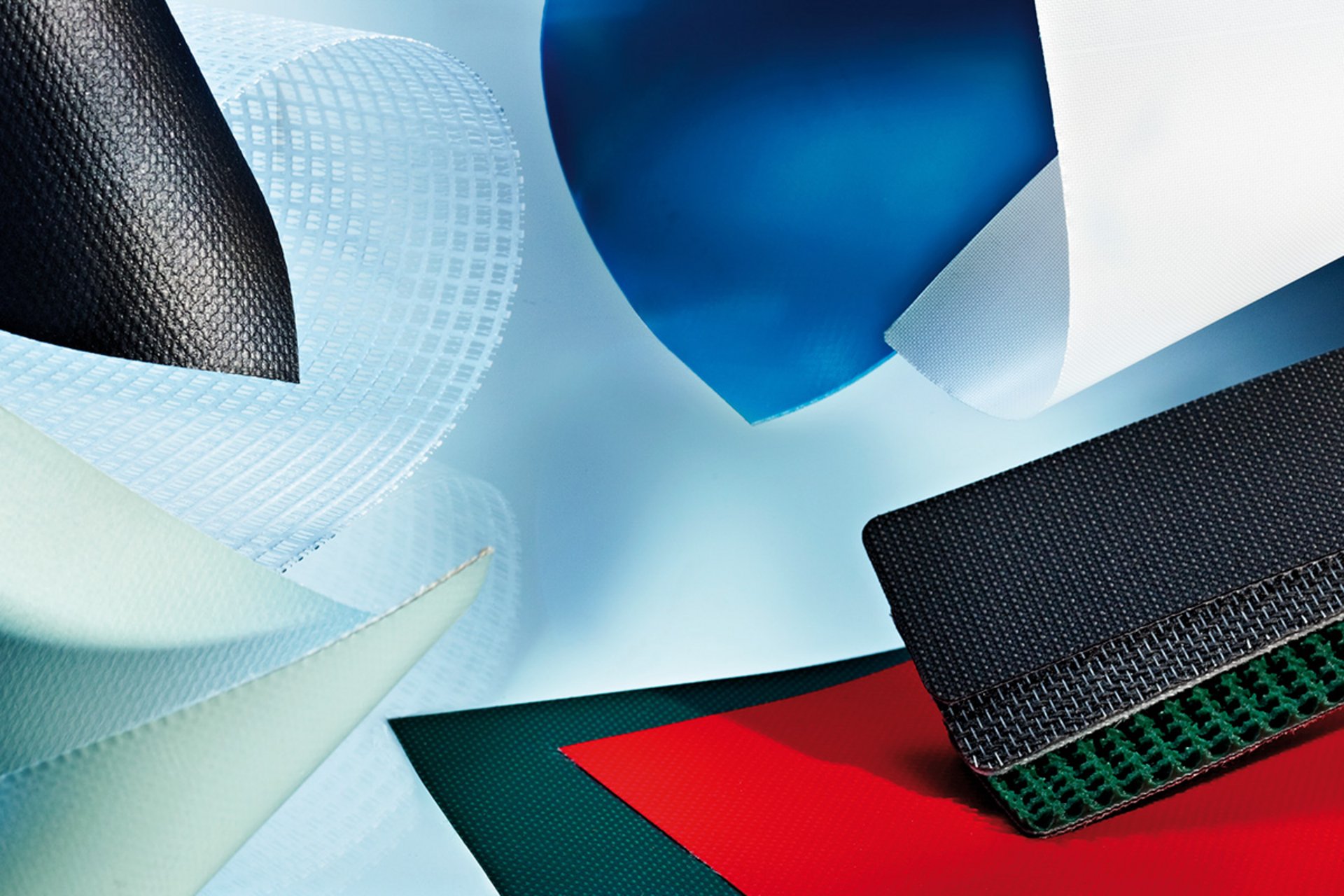

Technical textiles industry

Our demanding customers from the textile coating industry know: High-quality end products can only be produced on high-quality machines and systems. This is why, in cooperation with your experts, we realize simple and highly complex plant concepts exclusively with Olbrich machines. Including perfectly coordinated drive and switchgear technology.

Your advantage at OLBRICH: You can realise different product variants from the field of technical textiles on a single system. Our engineers, chemists and process engineers develop reliable state-of-the-art technology for you - with more than 70 years of experience in the tarpaulin, conveyor belt and artificial leather industries. All our knowledge from other industries is incorporated into each of your projects.

Coating technical textiles

With OLBRICH coating systems you are opting for maximum precision. In this way you can achieve high-quality coatings on a wide variety of materials in the field of technical textiles, such as banner fabrics, tarpaulins, tents, membranes and artificial leather goods. Coatings for other applications are also possible, such as industrial and conveyor belts or open mesh, boat, pool and sun protection products.

The flexible working widths of your OLBRICH systems open up many production possibilities for you: You can coat tarpaulin, membrane and banner fabrics in areas from 1,800 to 5,400 millimetres, the widths for transport systems (PVC/TPU) are between 1,800 and 4,200 millimetres. For artificial leather products (PVC/PU), widths from 1,400 to 2,400 millimetres have established themselves in the market.

Our specialists are also happy to implement combined systems for you, for example for coating, varnishing and laminating tarpaulin fabrics. Or plants for the production of artificial leather - from coating to finishing (embossing/lacquering).

Exemplary PU/TPU/PVC coating technologies:

- Air knife

- Knife over roll coater (KOR)

- Roll coaters (RC)

- Reverse roll coater (RRC)

- Dip Coating/Foulard

- Gravure Coating/Varnishing

- Transfer coating

- Pressurized doctor chamber

- Dual-Layer Slot Die

- Other combined machines

Printing and varnishing technical textiles

High-quality surface finishing of your technical textiles can be achieved safely and efficiently with OLBRICH systems and machines. Possible areas of application are protective or top coats, surface design (pool liners) or the coating of glossy or matt surfaces. In this way you not only achieve the desired optical or haptic effects, but also weather, scratch and dirt barriers.

The maximum system widths are between 1,600 and 5,400 millimeters, the coating weights (wet) are typically eight to 60 grams per square meter. Your OLBRICH systems and machines are equipped with fully automatic gap and pressure controls for maximum repeat accuracy in conjunction with recipe management systems.

In this way, you can produce high-quality prints and coatings on many textile products, for example on banner fabrics and tarpaulins, artificial leather goods, tents and membranes. However, solutions for other applications are also possible, such as industrial and conveyor belts or boat, pool and sun protection products.

Our specialists will also develop tailor-made individual or combined systems for you for the subsequent work steps, such as smoothing or embossing of the applied and painted coating masses.

Exemplary printing and coating technologies:

- Offline systems for high speeds

- Inline systems for finished products in one pass

- Strip printing systems

- Lacquering technology for water/solvent-based systems

- Forward or Reverse coating

- Special lacquer pump and heating systems

Drying technical textiles

As a specialist for drying technical textiles, OLBRICH offers you a particularly wide range of machines with a wide variety of drying technologies. Depending on the product, you can choose between top air systems with optimum ease of cleaning or a combined top and bottom air system for high performance with heavy coating weights.

Your advantage at OLBRICH: Our specialists design each dryer or gelling oven individually for your production - from the type of heating to the ideal nozzle system.

We optimally adjust the length of the system to your production speed. All drying temperatures are variable and average between 50 and 230 °C, but we also develop special systems with hot-air ovens up to 400 °C for you.

In this way you can easily realise the high-quality drying of textile products, for example banner fabrics and tarpaulins, artificial leather goods, tents and membranes. However, solutions for other applications are also possible, such as industrial and conveyor belts or boat, pool and sun protection products.

Our specialists are also happy to implement combined systems for you, for example for coating, varnishing and laminating tarpaulin fabrics. Or plants for the production of artificial leather - from coating to finishing.

Exemplary printing and coating technologies:

- Air dryer

- Upper and lower air dryers

- Dryer for solvent products

- Hot air ovens for foams

- Vertical and horizontal dryer systems

- Re-Circulating air dryer

- Gelling ovens

- Annealing ovens

- Foam ovens

- Radiation dryers

- Stenter frame dryer

- Infrared heating systems

Laminate technical textiles

With systems and machines from OLBRICH, you can laminate your technical textiles in all desired variations - because we develop perfect solutions for you using a wide variety of processes. For example, you can easily combine PVC/PU films with textile webs or realise multiple laminates from thick PVC/textile coatings for heavy conveyor belts.

The flexible working widths of your OLBRICH systems open up many production possibilities for you: For example, you can laminate tarpaulin, membrane and banner fabrics in areas from 1,800 to 5,400 millimetres. The widths for transport systems (PVC/TPU) are between 1,800 and 4,200 millimetres. Widths from 1,400 to 2,400 millimetres are possible for artificial leather products (PVC/PU). Our laminating lines are suitable for different product areas and can work with high line forces in the laminating on request.

Possible line variants for the production of your technical textiles are multiple laminating lines (double to sixfold) or combined lines that perform several work steps one after the other - for example laminating and smoothing or embossing and lacquering.

Exemplary laminating technologies:

- Wet lamination behind coating machines

- Hot lamination with heating drum and/or infrared technology

- adhesive lamination

- Laminating or delaminating of papers or films

Embossing and smoothing technical textiles

With the know-how of our mechanical engineering specialists, you can give your technical textiles high-quality three-dimensional surfaces. In this way you achieve an optical or technical upgrading of your products, for example by deep embossing, matting or smoothing.

The flexible working widths of your OLBRICH systems open up many production possibilities for you: You can emboss and smooth tarpaulin, membrane and banner fabrics in areas from 1,800 to 5,400 millimetres. The widths for transport systems (PVC/TPU) are between 1,800 and 4,200 millimetres. Widths from 1,400 to 2,400 millimetres are possible for artificial leather products (PVC/PU). Our machines can be used in a wide variety of plant areas and can also be retrofitted to existing plants.

In this way, you can achieve high-quality embossing and smoothing of textile products, such as banner fabrics and tarpaulins, artificial leather goods, tents and membranes. However, solutions for other applications are also possible, such as industrial and conveyor belts or boat, pool and sun protection products.

Exemplary embossing/smoothing technologies:

- Embossing machines

- Embossing in repeat/register

- Turret embossing for quick design changes

- smoothing calender

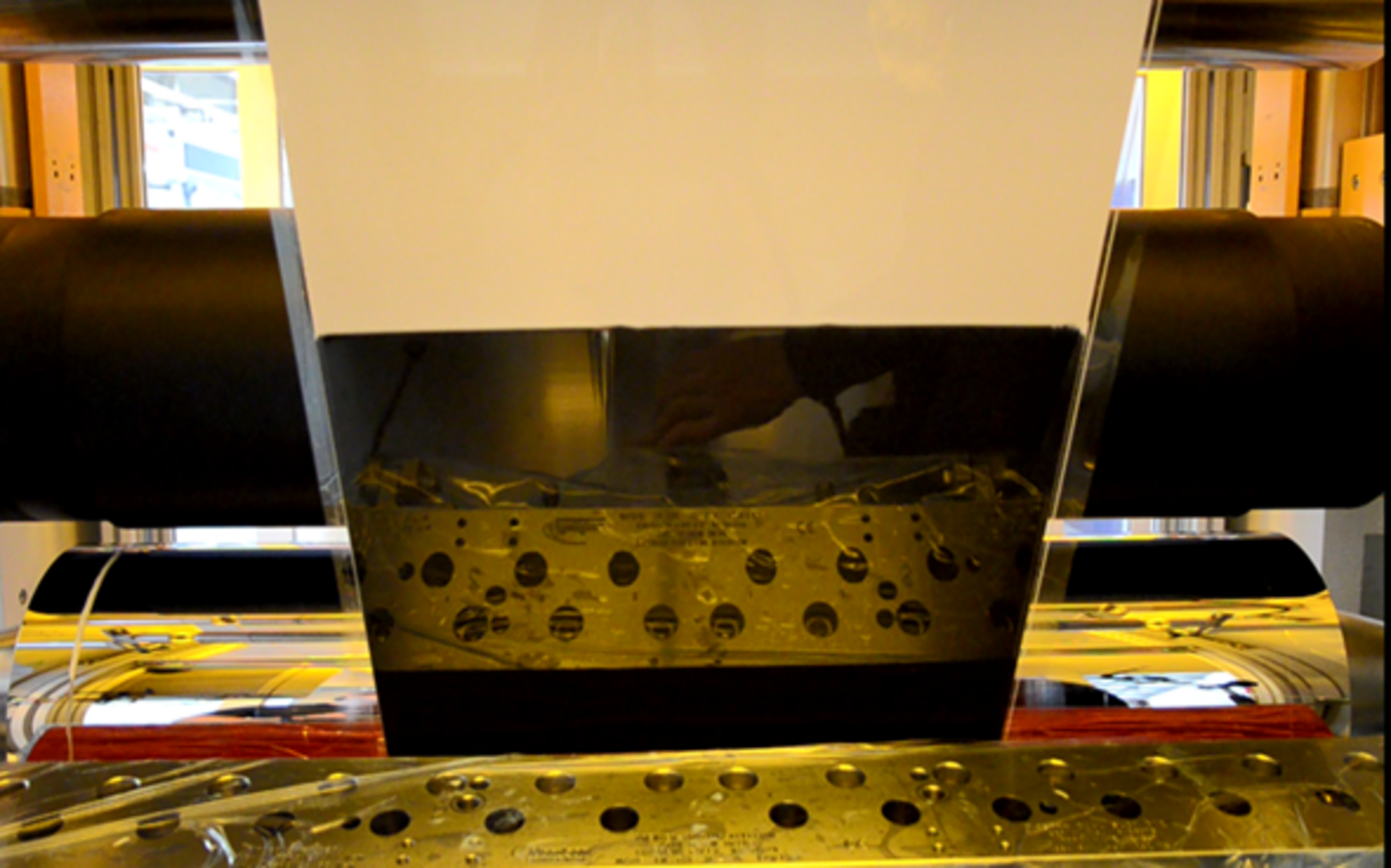

Calender coating for technical textiles

OLBRICH melt roll calender lines for the production of technical textiles not only guarantee you the highest precision in all components, but also the greatest possible variety with regard to carrier materials and coating masses. With our machines, for example, you can easily produce open and closed woven and knitted fabrics or Raschel fabrics with coating masses of 60 to 2,000 grams per square meter.

The flexible possibilities of your OLBRICH systems also open up many production possibilities, for example in the processing of S-PVC, TPU, TPO, EVA, EPDM, PP or CSM. In addition, you can produce tarpaulin, conveyor, membrane and banner fabrics in ranges from 1,800 to 4,400 millimeters. In this way, you can achieve a high-quality coating of textile products using the melt-roll calendering process. However, solutions for other applications are also possible, such as industrial doors or boat, pool and sun protection products.

Our specialists will also be happy to develop combined lines for you, for example coating calenders with a precoating stage, another calender for the laminated film product and a downstream embossing machine.

Exemplary calender technologies:

- Two-roll melting calender

- Three-roll melting calender

- Calandrette with slot-die coating

Winding technical textiles

With OLBRICH you can rely on reliable production processes when winding your products. All components are designed and perfectly coordinated by our own machinery experts - from unwinders and rewinders to technology for switchgear and visualisation systems.

The flexible working widths of your OLBRICH systems open up many production possibilities for you: For example, you can wrap tarpaulin, membrane and banner fabrics in areas from 1,800 to 5,400 millimetres. The widths for transport systems (PVC/TPU) are between 1,800 and 4,200 millimetres. Widths of 1,400 to 2,400 millimetres are possible for artificial leather products (PVC/PU).

You determine the degree of automation yourself: We offer a comprehensive range of different systems - from manually operated single winders to fully automatic turret winders. The winding core is picked up either by expansion shafts or mandrels.

In this way, you can achieve high-quality winding of textile products, such as banner fabrics and tarpaulins, artificial leather goods, tents and membranes. However, solutions for other applications are also possible, such as industrial and conveyor belts or boat, pool and sun protection products.

Exemplary winding technologies:

- Single-station winder

- Double winder

- Turret winder

- Finished roll winder

- Jumbo roll winder

- Small roll winder

Technical textile finishing

Complete your production with efficient finishing systems from OLBRICH: We offer you a large selection of unwinding and rewinding devices, which our machinery specialists fit seamlessly into your system concept. Your textiles can be finished either manually or with automatic reel change, so that you benefit from significant time savings during daily production.

The flexible working widths of your OLBRICH systems open up many production possibilities for you: For example, you can produce tarpaulin, membrane and banner fabrics in widths ranging from 1,800 to 5,400 millimetres. The widths for transport systems (PVC/TPU) are between 1,800 and 4,200 millimetres. Widths from 1,400 to 2,400 millimetres are possible for artificial leather products (PVC/PU).

In this way you can achieve high-quality packaging and labelling. of textile products such as banner fabrics and tarpaulins, artificial leather goods, tents and membranes. However, solutions for other applications are also possible, such as industrial and conveyor belts or boat, pool and sun protection products.

Exemplary packaging technologies:

- Single rewinder/unwinder

- Double rewinder/unwinder

- Turret winder

- Reeling systems

- Packaging facilities

Technical textiles: drive and control technology

Maximize your production and data security: With drive and control technology from OLBRICH, you can rely on safe and validated processes in the production of technical textiles. In this way, you receive all services from one experienced source: We supply you with the mechanical drive and suitable switchgear with OLBRICH state-of-the-art technologies for your plant.

Your added value at OLBRICH: Our specialists are familiar with all drive and control variants. For the European and American markets, we realize cable markings and cable routes in addition to the usual standards. In addition, we have a dedicated contact person for each automation area at your side.

With our own specialists in the electrical sector, we implement innovative and safe solutions for you in the areas of drive and control technology, user interfaces and visualisation systems. The well thought-out architecture of our systems also enables you to retrofit functions and aggregates at a later date. In addition, we also retrofit older systems with state-of-the-art technologies.

Exemplary services for drive and control technologies:

- Conception and Realization of Drive Technology

- Switchgear design and manufacturing

- Software engineering for CPU

- Visualization systems

- Support and assistance with IQ and OQ

- Service over the entire life cycle

- Retrofittings and Upgrades

Services in a full-service package

We implement your individual project in six carefully coordinated steps: